“During the Second World War, almost every motorised vehicle in continental Europe was converted to use firewood.” – Kris De Decker, Low-tech Magazine

What is gasification?

It’s turning biomass (often wood chips and offcuts) into usable gas. The flames we see in an open log fire are actually the burning of gas from the wood – about 70 to 80% of its total mass. If wood is heated but then starved of oxygen, so that it doesn’t burn with a flame, gas is released and char is left behind (this is the ancient method of charcoal production). This wood gas (called ‘producer gas’) has a high calorific value that can then be transformed into kinetic energy by combustion in an engine cylinder, and into grid-independent energy if the engine is attached to a generator. This heating without oxygen is called pyrolysis – which is just a stage in, and not synonymous with, the gasification process.

Gasification is not a new technology. Coke and coal gasification in the 1850s was followed in the early part of the 20th century by systems that could accept wood scraps and agricultural residues, reaching a technological peak during the 1930s and 40s. It changes a bulky fuel into a gas that is easier to transport, burns cleaner, and burns hotter. Internal combustion engines (both spark and compression types) can be converted to run on producer gas, and during the Second World War, when there were shortages of petroleum and diesel, wood-fuelled vehicles became relatively common. System use later declined when oil became cheap, but some countries – particularly in Scandinavia – continued to use the technology. Interest has returned because of global warming and future fuel insecurity.

Small-scale gasifiers also have the potential to turn any carbon-based waste (old shoes etc) into energy. They’re not at this stage yet, but expect to see many more of these systems in future. Large-scale gasification and pyrolysis as a way of turning municipal solid waste into energy is subject to increasing investment due to the bad press that incineration has received, and government subsidies for novel waste-to-energy systems. So far, the track record of large-scale systems is poor, due to the variable nature of the waste, with numerous failed projects and system shut-downs for exceeding emission limits or for poor operational performance.

Little experiment: making a generator that is run from a tiny wood gasifier.

What are the benefits of gasification?

Biomass gasifiers have an advantage over wind and solar renewable technologies because they provide power and heat on demand rather than being limited by seasonal or diurnal variations in supply. There is no need to store energy. The systems operate like a car with a fuel tank of wood chips. Make the engine run faster and the wood will be used up more quickly; run it more slowly, or switch it off completely, and the wood will last as long as needed. They can be more efficient than a biomass boiler as they have no water-heating requirements for energy transfer.

Gasifiers produce lower concentrations of NOx and SOx pollutants than combustors. The wood char-ash which gasifiers produce as a by-product can also be used as a soil fertiliser/conditioner.

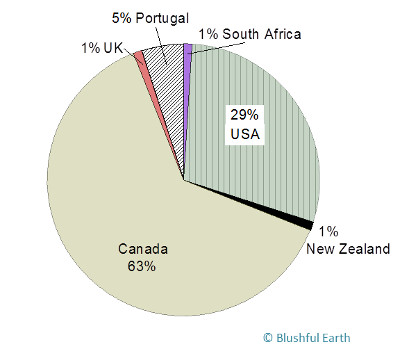

Biomass is only an ethical and sustainable energy source if plant regrowth equals removal, and if no associated fossil-fuel energy is used. Due to the large volumes required, demands on suppliers to be reactive to market requirements, and the extra costs involved in locking in large areas of space, biomass supplied to power stations is usually force dried in large fan-assisted ovens, pelletised, and transported internationally. Small-scale use of bio-waste does not have these associated carbon inputs, and it doesn’t necessitate the use of quality agricultural land.

Small-scale gasifiers will be cost effective where there is a waste wood resource for free. When land is cleared or timber harvested, anything other than heartwood is chipped anyway, and either left in situ or landfilled. It has zero or negative value since landfill disposal is costly. This has possible community enterprise potential, making use of local authority waste. In the developing world, gasifiers can provide something that the grid cannot – reliable electricity for industry.

What can I do?

Biomass gasification reactors are simply steel vessels filled with wood chips. With one or more small openings to permit some air to enter, they are connected directly to an engine, and the engine suction pulls the gas through. They need no external water, electricity or gas, as they self-sustain their internal temperature. Reactor designs have changed little since the 1920s, and are based around three main types: updraft, downdraft, and cross-draft. There are also fixed and fluidised bed gasifiers (air or steam gasification), but these are industrial-scale systems. Downdraft, fixed-bed gasifiers are the most widely used, as they produce high-purity gas with relatively low quantities of tar.

For anyone with basic fabrication skills, small biomass gasifiers can be self-built, and full details of sizings and components can be found in our publication, Gasification: Succeeding with Small-scale systems. There are a number of companies offering commercial systems – such as GEK, Volter and Ankur. These are not at present, ‘push-button’, low-user interaction, kitchen-type appliances, but they’re getting there. Made from sturdy basic components, gasifiers are at present much like a classic car, which needs routine maintenance to ensure reliability, but which could last a lifetime. Specialist biomass gasification consultants are rare.

Gasifiers are proven to work with wood chips, but poor-quality wood chips can lead to problems if the set-up is not right. In particular, before buying a system, look for the small print about what the feedstock requirements are, since some (but not all) systems will stipulate wood chip moisture levels below that which can be achieved naturally. Fines content can also be a problem. Outside of design specification feedstock range, temperature in the reactor varies and tar comes through in the gas, which can clog engine pipework. Some systems use water scrubbing to clean tar from the gas, which can result in high disposal costs throughout the lifetime of the system. Others use basic wood chip filters, which work effectively.

Wood gas comprises about 20% carbon monoxide, which is fatal if inhaled. However, considering that oil and petrol are highly flammable, carcinogenic liquids, producer gas just poses a different hazard. Operating temperatures inside the reactor are between 800-950°C for optimum clean gas. The gasifier reactor is silent when operating, but the engine will be noisy. It’s perfectly legal to own and operate a wood gas vehicle, and as they only produce smoke at start up and shut down, they can be used in smokeless zones.

Wood gas generators are stand-alone, but can be grid-tied. In the UK, they are presently not eligible for feed-in tariffs, but system owners can get credits from ROCs and income from the Renewable Heat Incentive, although there are caveats.

And finally – remember Wacky Races? The Arkansas Chuggabug with Lazy Luke and Blubber Bear? Pretty sure that’s a gasifier at the back there.

Thanks to Dr. Andrew Rollinson of Blushful Earth for information, and Low-tech Magazine for the main image.

Resources

Bridgewater, A.V. (2003). Renewable fuels and chemicals by thermal processing of biomass, Chemical Engineering Journal, 91, pp. 87-102.

Food and Agriculture Organization, 1986, Woodgas as an engine fuel, Forestry Paper 72, United Nations: Rome, pp. 1-139.

Jain, B.C. (2000). Commercialising biomass gasifiers: Indian experience. Energy for sustainable development, 4 (3), pp.72-82.

Kirkles, F. A., Verbong, J.P.G. (2011). Biomass Gasification: Still promising? A 30-year global overview. Renewable and Sustainable Energy Reviews, 15, pp. 471 – 481.

OFGEM Annual Sustainability Report Dataset, 2012, [accessed 11th April 2014]. Available from: https://www.ofgem.gov.uk/publications-and-updates/annual-sustainability-report-2011-2012

Reed, T., Das, A. (1988). Handbook of Biomass Downdraft Gasifier Engine Systems, Solar Energy Research Institute: Colorado, pp. 1-140.

Ruiz, J.A., Juarez, M.C., Morales, M.P., Munoz, P., Mendivil, M.A. (2013). Biomass gasification for electricity generation: review of current technology barriers. Renewable and Sustainable Energy Reviews, 18, pp. 174-183.

Stassen, H.E. (1995). Small-scale biomass gasifiers for heat and power: a global review. World bank technical paper no 296. The World Bank: Washington DC, pp.1-88.

Whittaker, C., The nature of the wood pellet supply to the UK, 2014. In: Torrefaction Workshop, University of Leeds, 2-3 April 2014.

The specialist(s) below will respond to queries on this topic. Please comment in the box at the bottom of the page.

Andrew Rollinson of Blushful Earth has an MSc in Energy and Environment, and a PhD in philosophy. He is a renewable energy specialist who has worked on small-scale renewable energy projects, and collaborated on sustainable engineering systems in many parts of the world. He is author of our book, Gasification: succeeding with small-scale systems.

The views expressed here are those of the author and not necessarily lowimpact.org's

4 Comments

-

1Tony Lockman March 13th, 2021

Hi Dr Rollinson, thank you for a very interesting and informative basic introduction to Gasification.

I have been somewhat fascinated by alternative energy technologies for many years since I first came across a copy of The Mother Earth News – Handbook of Homemade Power in the late 1980s (printed in 1974), long before the Internet made its way into households.

At that time I was particularly interested in the Anaerobic Digestion of manure and was fascinated by the article about a Pig Farmer who set up his whole farm to run on the waste from the pigs. One other article in this book mentioned that whilst this process was suitable for human waste, the flush toilets we use are not conducive as it introduces too much water into the mix to support the digestion process. I did write a letter to the author at the time asking if the newer “half flush” systems would address this problem but received no reply. I have since drawn the conclusion that even these would still introduce too much water.

Fast forward to the present, and Anaerobic Digestion appears to have dropped out of the spotlight in favour of Pyrolysis.

It was whilst researching Pyrolysis online I came across your 2018 Blog completely dismissing ‘plastic to fuels’ as a viable or sustainable solution to the plastics problem.

I am quite perplexed by the fact you are such a staunch proponent of biomass gasification, yet so intensely biased against pyrolysis of plastics. I also felt you prejudiced your argument by likening a self-sustaining plastic pyrolysis to a perpetual motion machine or “perpetuum mobile”. Yes, the laws of thermodynamics do come into play, but we are not talking about a closed loop system here, it is only a question of whether the energy released from the feedstock is greater or less than the energy required to release it (including inefficiencies). My online research to date suggests it is feasible, but I will return to that later. You further muddied the waters of your argument by basing it on MSW (Municipal Solid Waste), yet encompassing all plastics in your comments. More too on this later.

I agree with you that Gasification is an exciting process with lots of potential. If managed correctly, it is literally a 100% renewable. It does however have its drawbacks.

1. Woodgas is corrosive. This is a problem which must be taken into account both with the production and use of it. In your blog you made several references to using it in Motor Vehicles but what you did not mention is the damage caused to the Motor Vehicles and shortened longevity. This means repairs and replacements will be more frequent resulting in an additional cost to the environment. At present, replacement of a Motor Vehicle also means more plastic production.

2. Woodgas is inconvenient as an alternative to fossil fuels in Motor Vehicles. It is extremely difficult to regulate the rate of production of Woodgas in a Gasifier, yet the consumption of a Motor Vehicle varies greatly, from stop/start traffic to long highway drives, to stopping at the supermarket to do your shopping. These are all very challenging when in its most basic form, the production rate of a Gasifier is constant.

In my opinion, Gasification is only truly feasible in a stationary application, notwithstanding your references to the Wacky Races and the Arkansas Chuggabug (as a child I asumed it was a steam powered vehicle, but now I see it has an internal combustion engine in front so therefore it must be a Gasifier as you said), and the ‘Mr. Teslonian’ pickup truck. If Gasification in a Motor Vehicle was truly feasible, people would have fitted Gasifiers to their vehicles during recent petrol price hikes. In fact, it was only shortage of supply, not price which led people to turn to this technology during the Second World War.

Enter Pyrolysis of Plastics.

I, like you, would love to see single use (and for that matter ANY) Plastics removed from our lives, but the simple reality is, it’s not going to happen. Sure, there are multiple initiatives around the “reduce, reuse, recycle” mantra, but none of these are ever going to result in 100% removal of plastics from society. You can’t put the Genie back in the bottle.

That said, there is hope. There is a growing range of Bioplastics appearing, some genuine, some decidedly deceptive. Two genuine examples spring to mind; PLA (polylactic acid) and Bio-PE (biopolyethylene). The latter is the most exciting:

Conventionally PE is a fossil fuel derived plastic however it is entirely possible to obtain PE’s monomer ethylene from a renewable resource and thus generating bio-based PE. Bio-ethylene is normally synthesized from the catalytic dehydration of bio-ethanol, which itself is generated from first- or second-generation fermentation of biomass. The theoretical energy requirement to pyrolyze 1 kg of PE is 1.047 MJ and can generate around 72–84 wt.% liquid oil. The energy value of the oil is around 43 MJ/kg so the energy profit is very high for this process. Definitely not a “perpetuum mobile”.

In your 2018 Blog, you seemed to fixate on electricity as the energy source for Pyrolization, however I would assert that is the least energy-efficient option and would instead opt for the burning of a fuel source. One “YouTube” video I came across advocated the use of a Babington Burner which makes sense due to its ability to utilise a wide range of liquid fuels including waste Motor Oil, waste Cooking Oil, or virgin oil from renewable sources such as vegetable or Canola. Another possibility is Woodgas from Gasification!

As others alluded to in the comments on your 2018 blog, something needs to be done about plastics in landfill. As you have correctly identified, Pyrolysis of MSW is not feasible and is unsustainable, however I put it to you that Pyrolysis of pure plastics is an elegant solution to the recycling of this undesirable yet inevitable waste product. I would dearly love to live in your utopian world where plastics are nonexistant, however in reality this is never going to happen in our lifetimes. Isn’t it far superior to “depolymerize” these into replacements for fossil fuels than consign them to landfill or do you have an alternative strategy to prevent them ending up in our landfills and oceans?

I agree that the sorting of plastics out of MSW is prohibitive, so why not mandate consumers do the sorting before disposal?? I’m sure appropriate incentives/disincentives could be put in place to ensure this is done effectively.

I truly wish I had an MSc and PhD like you, but unfortunately am only a graduate of the “university of life” and “Scholar of YouTube”, but am quite prepared to back up my opimions with practical experiments if necessary.

I look forward to your response.

-

2Andrew Rollinson March 15th, 2021

Dear Tony,

“Graduates of the university of life” are historically the ones who have understood woodgas to engine/gasifier systems and at the same time been able to succeed with them. There are few people around who fall into this category. Ask them and they will tell you that such systems cannot operate with plastic as a feedstock. It is common knowledge.

Plastic may have a high energy density, but the internal thermodynamics of such a reactor are extremely sensitive to properties such as friability, fixed carbon content, and others. It clogs the reactor and impairs the product. This is one technical reason why I am ‘for’ wood gasification, and ‘against’ plastic gasification and pyrolysis. The latter is a white elephant, and a dangerous distraction.

You say that your ‘online research suggests that plastic “chemical recycling” may be feasible. When someone has operated a plant at commercial scale with a net positive energy balance – and created a product of useful quality and quantity mind you – come back to me and I’ll happily discuss further.

Andrew

-

3Shuttsey October 20th, 2021

Andrew, The Gasification/Pyrolysis of plastics is a good process and yes, it does have a downside but much of the clogging can be eliminated by burning at very high temperatures (3500-4000 F) You will end up with slag at the bottom, which is still a usable product. New bio-plastics are truly the way to go but, we must come up with ways to eliminate plastics as it is produced. NOT RECYCLE, eliminate. Just thinking out loud!

-

4Andrew Rollinson October 25th, 2021

Shuttsey:

For material reasons it is fanciful to suggest operating at 2000C, not just the reactor casing, but the tuyeres, and how will you attain and maintain this temperature? The clogging occurs because plastic is amorphous, and there must be a temperature gradient from ambient to 2000C across which the feedstock must pass. It is physical as much as chemical.

Such ideas were explored an abandoned over 100 years ago..

Andrew

Biodiesel

Biodiesel

Biomass boilers

Biomass boilers

Charcoal making

Charcoal making

Low-impact transport

Low-impact transport

Tree / woodland management

Tree / woodland management