The Wool Journey Part 9: the first stages of preparing to spin

In Part 9 of The Wool Journey guest blog series from The Natural Fibre Company, Sue Blacker takes us through the first stages of preparing to spin, featuring the Fearnaught machine and more.

As with home decorating, the amount of work done in preparation for spinning is (and feels like) much more than the actual final painting or papering! So far, we have moved from the first of the pictures below … and are now heading for the second (the end result of which is pictured above) … the third is still some way farther through the mill!

So the next processes of teasing, blending, carding and combing are just as important to improve the end result as all the work already done by the farmer to produce and harvest the fibre and the sorting, grading, scouring and drying.

Teasing and blending

To make felt or to spin yarn, it is necessary to separate the scoured fibres, which may have clumped together in scouring, drying and packaging in bales. This may be done by hand and is most easily achieved when the fleece is still slightly damp from washing.

Teasing by machine: the Fearnaught

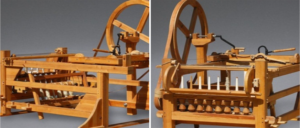

Here is our Fearnaught! It is the old one, showing the machine open for cleaning and also the cage in which it lives to keep everyone safe when it is working.

The Fearnaught is a rotating machine with rollers covered with spikes, which no doubt led to its name! These machines are kept in cages with time delay locks on the gates so that they cannot be opened during operation and until several minutes after the machine has stopped, to prevent the risk of damage to people. The rollers are set carefully so that wool, mohair and alpaca can go safely through them and the effect is like brushing hair, to separate and remove the tangles.

A machine similar to a Fearnaught can also be used to separate or de-cott matted greasy fibre. Also longer fibres which may snarl up the carding machine or Fearnaught may be chopped in advance of blending or carding. A swinging machine called a picker is also sometimes used for teasing by smaller scale hand spinners – and as the photo’s show needs careful handling!

Generally it is easier and makes a better yarn for hand knitting to have a mix of different diameters and lengths of fibre than with completely consistent fibre. However, for really fast processing in weaving and machine knitting more homogeneous fibre can be helpful as the resulting yarn should be more even provided it is made on correctly calibrated and set up equipment.

At The Natural Fibre Company the equipment is designed to process the majority of British Breeds wools – this means that very coarse wool such as Devon and Cornwall Longwool or Herdwick or very fine Merino-style wool, cashmere, and very fine alpaca may not have such good yields (unless from pre-prepared tops) and may produce less even yarns – we only have one each of most of these machines and cannot re-wire or re-nail a carding machine or Fearnaught or change the fallers on a worsted machine for every batch.

Blending: the Fearnaught again

These pictures are from our new machine when it was being installed and give a close-up of the teeth on the rollers which tease apart the scoured wool.

The Fearnaught can also blend at the same time as teasing, which enables different fibres to be blended together:

- black with white to make a grey or brown with white to make a fawn

- mohair with wool for a hard-wearing sock yarn or more vibrant dye effects

- the addition of alpaca, cashmere or finer softer wool to improve the handle, and possibly also to add colour

- the addition of silk to help hold together short fibres or add a touch of luxury

- blending downland wool with upland wool to make the perfect carpet yarn

- adding shorter, denser wool to coarse long wool to enable it to be spun

- adding vegetable fibres such as bamboo, rose, nettle, linen or hemp

Each of these options needs to be done in the right order in a mixed mill in order to minimise the risks of cross contamination between colours or fibre types and avoid having to clean down between every batch, which is another reason why large-scale industry and flocks have tended to stick to white – the easy but boring option!

This is also why some orders take longer than others to make by The Natural Fibre Company, as we generally work from white through to black and from fine through to coarse after the periodic cleaning of our blending and carding equipment. It is also why we have to limit the times when we are able to process organically, as this requires complete cleaning of all equipment and segregation of the fibre, and the same applies to Herdwick as the fibre is particularly prone to spread everywhere and can damage other batches. This is also why we do not as a rule process wool which has been already dyed, as red in particular has a terrible tendency to show up everywhere!

Generally the blending is done to mix colours or fibre types, and sometimes needs to be done twice to ensure the mix is even throughout the whole batch, such as when mixing black and white in Jacob wool for instance. When vegetable fibres are added, this will alter the resulting yarn much more, as they will not take dye in the same way as the protein animal fibres.

When blending the proportions are also important: a 50/50 mix will have an even balance of the characteristics of both fibres used, while less than 25% will add some difference, such as softness, durability or lustre, without completely altering the nature of the 75% proportion. Colour being what it is, with alpaca fibre having more intense natural colour than wool, means that blends with coloured alpaca are not easy to replicate from batch to batch. This is the joy of small batch, farm yarn and provenance, and can be a major marketing opportunity, although it not always perceived as such by consumers or larger manufacturers!

Adding cotton is more difficult for most wool spinning mills as the very short staple of cotton, with the longest being only 1.5 inches, or 3cm, compared to wool ranging generally from 2 inches or 5cm upwards means that cotton will tend to fall out of the machines. Similarly specialist spinning equipment is needed for yarns to be made out of re-cycled yarns and garments, as again the fibre will be very short, although a proportion can be added to a wool yarn to create specific effects.

At the same time as blending the fibres and colours, around 10% by weight is added to the batch of water (7%) and spinning oil (3%) which keeps the fibre under control through the further processes and also enables it to slip well through the machines. If a yarn is to be further machine processed in weaving or machine knitting this oil is left on it to help with the next stages. For a hand-knitting yarn, the oil is washed out after spinning and plying, either before finishing or in the dyeing process. For rovings for hand spinning or felting, no oil is added.

At The Natural Fibre Company we use a vegetable based spinning oil which is organically approved for all woollen spun yarns and are working on getting something acceptable and workable for worsted spun yarns. We may also sometimes use periods of rest between processed, anti-static sprays and talcum powder to help get the fibre through the machines.

To summarise therefore, the teasing and blending process takes the clean scoured yarn to a pile of “fluff” separated out, with colours and fibre types evenly blended with a little oil and water added, ready for carding.

About the author

About the author

As British wool spinners, The Natural Fibre Company add value by processing quantities of fleece from 20 kilograms up to over a tonne and more. As we scour, card, dye and woollen and worsted spin under one roof, we are effectively experts in all aspects of the process of turning raw fleece into high quality yarn. Most of our customers are in the UK for rare and specialist breeds.

The views expressed in our blog are those of the author and not necessarily lowimpact.org's

The Wool Journey Part 1: what is wool?

The Wool Journey Part 1: what is wool?

The Wool Journey Part 2: wool attributes – thickness

The Wool Journey Part 2: wool attributes – thickness

The Wool Journey Part 3: wool attributes – length, crimp and lustre

The Wool Journey Part 3: wool attributes – length, crimp and lustre

The Wool Journey Part 4: wool attributes amongst breeds, natural colour and health

The Wool Journey Part 4: wool attributes amongst breeds, natural colour and health

The Wool Journey Part 5: harvesting the wool

The Wool Journey Part 5: harvesting the wool

The Wool Journey Part 6: grading, sorting and storing of fleeces following shearing

The Wool Journey Part 6: grading, sorting and storing of fleeces following shearing

The Wool Journey Part 7: uses of different fibre types

The Wool Journey Part 7: uses of different fibre types

The Wool Journey Part 8: wool scouring and drying

The Wool Journey Part 8: wool scouring and drying

The Wool Journey Part 10: using traditional carding machines

The Wool Journey Part 10: using traditional carding machines

The Wool Journey Part 11: which yarn to make?

The Wool Journey Part 11: which yarn to make?

The Wool Journey Part 12: spinning at last!

The Wool Journey Part 12: spinning at last!

Alpacas

Alpacas

Felt making

Felt making

Knitting & crochet

Knitting & crochet

Low-impact clothes

Low-impact clothes

Sheep

Sheep

Spinning

Spinning

Weaving

Weaving