“Straw is perfect for a beginner. It’s easy to work with and you can make your house any shape you want. You can use straw to make any kind of buildings – from a four-storey office block to a house I know, which is a spiral. Go mad, have fun, start living!” – Steve James

What is straw-bale building?

It’s a building technique that uses straw bales (or even hay bales – although it’s best to use hay for animal feed) for walls – which can be load-bearing, or used to infill a timber frame. It was pioneered in the US mid-west in the 19th century by farmers whose only building material was the waste from their wheat crop. The buildings were intended to be temporary until conventional building materials were delivered. However, they found them to be solid, warm and comfortable, and many continued to live in them in preference to traditional houses.

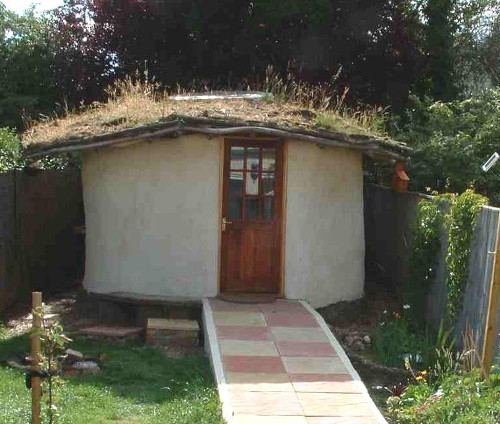

Walls can be rendered with earth or lime – breathable materials to protect them from the elements (see image).

Three common misconceptions are that they are a fire risk, they can house vermin, and they are not durable. None of these is true.

US tests have found that even unrendered straw-bale walls are less of a fire risk than timber walls (rendered walls are no more flammable than bricks).

Mice and rats are not attracted to straw as it is not a food source. They are attracted to holes though, but as long as walls are rendered, they won’t house vermin.

As for durability, there are 100-year-old straw-bale houses in the States. The wetter climate of the UK presents more of a challenge, but weatherproof rendering and a good moisture barrier means that there will be no problem, whatever the wall material.

In theory, there is no reason why a well-built and rendered straw-bale building with a solid roof shouldn’t last for at least 100 years and possibly a lot more. Furthermore, any problems can be rectified very easily.

What are the benefits of straw-bale building?

Environmental benefits

-

Straw bales don’t need to be fired like bricks, and don’t need cement, both of which use a lot of energy and cause pollution and greenhouse gas emissions.

-

They don’t need (often) environmentally-damaging insulation materials either, as straw has a much higher insulation value than brick or concrete.

-

This means lower heating bills / reduced CO2 emissions.

-

Straw is biodegradable.

- It’s also a way of capturing carbon and sequestering it in buildings.

-

Straw is a natural material, can be locally sourced, and if used in combination with other natural materials like timber, earth, slate and lime, means no toxins or ‘sick building syndrome’.

Other benefits

-

Cheap (bales usually cost around £3 each).

-

Easy and quick to build by non-experts.

- Good soundproofing.

- They look good (like a cottage but at a fraction of the price).

- Easy to modify.

- You can easily build curved walls and add alcoves etc.

- Each building is unique – no ‘little boxes’ with straw bales.

What can I do?

If you’re building a garden office, extension or storage shed etc., why not have a go at building it with straw bales? A small, single-storey building could be a good thing to practice on. Then who knows – you might graduate to building a straw-bale home.

First, do some reading, attend a course, and/or sign up for our online course.

If you intend to live in your straw-bale building, the first thing is to talk to your local planning officer. Getting planning permission depends on the local authority, the planning officer, and where you want to build, and not so much what you intend to build it from. There is nothing specific to straw-bale construction in the Building Regulations, but they certainly conform to criteria concerning health and safety, fire resistance and energy efficiency. Problems may arise either with neighbours or planning officials who are averse to anything new in their area. On the plus side, your ideas may fit in with the local sustainability agenda, especially regarding insulation levels and the use of natural materials.

When it comes to designing and building, there are many options for every part of the house. Foundations can be concrete, flint and lime, brick or timber pillars, or car tyres with rammed earth (foundations don’t need to be as deep as for brick houses). Roofs can be slate, tile, corrugated metal or bitumen, shingle or thatch. Floors can be concrete, earth or floorboards on joists.

However, we don’t recommend using cement / concrete on a natural build.

Introduction to our straw-bale building online course with Barbara Jones.

Bales are laid with each course offset, like bricks, with hazel stakes pinning the bales together. Smaller bales can be made using a baling needle (see image). Recycled materials can be used, including timber, doors and windows. Frames can be inserted during the wall-building process, and doors and windows fitted later.

If your build is timber-frame with a straw-bale infill, build your roof first, to keep your straw-bales dry. Otherwise, make sure you have lots of tarpaulin to hand to cover the bales and keep them dry until the roof is on.

You can self-build entirely, in which case you could invite lots of friends round for a ‘wall-raising’ weekend, or a lime rendering / earth plastering event. People will love it – just lay on lots of food and drink. Alternatively, you could employ a natural builder, or get professional help with plumbing, carpentry or electrics.

Thanks to Barbara Jones of Straw Works for information.

Whilst you’re here, why not take a look at the other 30+ shelter topics available? And don’t forget to visit our main topics page to explore over 200 aspects of low-impact living and our homepage to learn more about why we do what we do.

The specialist(s) below will respond to queries on this topic. Please comment in the box at the bottom of the page.

Phil Christopher is an environmentalist, builder and trainer and he believes in making a low-impact lifestyle an attractive possibility for everyone. Phil runs Huff and Puff Construction, specialising in straw bale and sustainable building, training and design. He’s a passionate advocate of earthen and lime plasters, stating “It’s the part everyone loves doing, even if they didn’t think they would!”

Phil Christopher is an environmentalist, builder and trainer and he believes in making a low-impact lifestyle an attractive possibility for everyone. Phil runs Huff and Puff Construction, specialising in straw bale and sustainable building, training and design. He’s a passionate advocate of earthen and lime plasters, stating “It’s the part everyone loves doing, even if they didn’t think they would!”

The views expressed here are those of the author and not necessarily lowimpact.org's

27 Comments

-

1Anthony Lamb January 19th, 2019

We built a straw bale house 9 years ago and have been delighted with the result. We are warm in winter and cool in summer. We attended a straw bale weekend class with the Dorset Centre for Rural Skills, we helped on a straw bale build with Barbara Jones and Bee Rowan and then helped on another one in Butleigh, near Glastonbury. Then we attended a 2 day clay plastering course with Bee at the Centre for Alternative Technology (CAT) in Machynlleth,Wales. Now we couldn’t be happier.

-

2caminodevuelta0 December 1st, 2019

Hi, i’d like to make a barn for goats of around 150-200 square meters so because it is a bigger construction than a house and needs greater height for animal ventilation, i was thinking about using big bales of 250-120-70 dimension.. would it work better like this? another question i have is that i was thinking about making an octagon but i don’t know if this is possible as there would be a lot of space void between 2 bales, specially with big bales, as the faces of the bales would not touch completely; so would it be possible to make an octagon construction with big bales and if so, how would it have to be made? thanks

-

3Phil Christopher December 2nd, 2019

Hi, Yes, it’s possible to use larger bales, especially if space is no object. You will potentially need more carpentry around them which may make the cost of that higher. I suggest shaping the ends of the bales so that they can fit together snugly. Use an alligator saw just like for standard bales.

-

4Anna Stam February 15th, 2020

Hi, my niece is buying a property in our hometown. She invited me to arrange her garden (BIIGG!!) and I can have the shed instead. I dream to make it a holidayhome. It’s a shed, made of bricks, and I would love to make a strawbale home of it. Wondering if I can built the outside, or maybe better the inside of the ‘shedhome’ with strawbales. Or is it not recommended both? Thanks for your advice anyway?Anna

-

5GwelTeg September 23rd, 2020

Hi folks! Im about to start on our barn straw bale build. Lots to do of course and inevitably delayed by covid unfortunately. What I am struggling with at the moment is finding construction grade bales. I may be being a bit of a luddite and not using the right search parameters, but in any case I would greatly appreciate the details of any suppliers please! Im based in North Cornwall. Thanks in advance!

-

6Phil Christopher September 23rd, 2020

Hi GwelTeg! There are specific suppliers who sell construction grade bales. Look for Colehay in Devon and Longhay in central England – there may be some closer to you that I am unaware of. Generally, Googling straw and hay merchants is a good first step. Also look for local horsey people/equine groups that will have sources for straw and ask who they use, or ask the same of dairy farmers – who use a lot of straw for bedding. Once you can get in touch with a supplier, speak to them about your bale requirements. Drop me an email if you like and I can send across a comprehensive list of questions – [email protected]. All the best, Phil.

-

7Bex Elliott October 17th, 2020

Hello. I live in a tiny Welsh stone cottage with a catslide roof at the back. I have always wanted to build an extension to create a larger kitchen/living space (I have always wanted to build a straw bale house but a pitiful lack of funding/knowhow/help will preclude that!). The plans I had drawn up (in a previous life when I had more money) were for an oak framed conventional build extension with a pitched roof at right angles to the main roof – I can’t see any other way to add space without taking a flat roof off the catslide which I am not keen on given the amount of rain we have. Is it possible to tie a straw bale extension into a stone house? And would it make a big difference to the cost? I assume there would be no extra complications using straw as the tricky stuff with the roof would be timber construction anyway….? Thank you.

-

8Phil Christopher October 17th, 2020

Hi Bex,

It’s certainly possible to add straw bale extensions to existing buildings and building with straw should not be any more expensive than other methods. General building advice often advocates building an extension from the same materials as the main property because the expectation is that everything will then settle out in a similar way, but with proper design consideration this should not be an issue.

You’ll be looking at about 500mm wide for rendered straw bale or straw panel walls, so consider if the wall thickness can be accommodated sensibly within the desired extension footprint. If space is very tight and thinner walls would make a significant difference, it might be worth looking at a timber framed or timber panel extension with wood fibre insulation or similar.

All the best,

Phil

-

9Bex Elliott October 17th, 2020

Hiya Phil. Thank you so much for your prompt reply. My house has walls almost that thick anyway, solid stone! Could never afford to build with that but thought the thickness of straw bale walls would tie nicely with the original house, and be a better environmental choice. Thanks again.

Bex

-

10Phil Christopher October 17th, 2020

Hi Bex,

Excellent, that sounds like good fit then. Let me know if I can help further. ?

All the best,

Phil

-

11Sam July 1st, 2021

Hello,

We are currently converting a agricultural timber barn under part Q planning. It will be a timber frame building. We have completed the strip foundations (concrete with concrete block on top), have installed Geocel foamglas subfloor insulation and under floor heating pipes, cork layer around the perimeter, and are just finishing the limecrete floor. Unfortunately we have had to put in a damp-proof membrane as we are in a radon area (between Geocel and the limecrete floor).

My question is….are we too late in the build to now use straw bales as infill between the timber frame as we have not got a wide enough strip foundation, and it is not itself insulated? And would the damp-proof membrane be an issue under the sole-plate?

It is a large area (200m2) so we could we overlap the walls in over the floor making the rooms slightly smaller?

I would love to incorporate straw bale building into our build, I just need to convince my timber framing husband!

Many thanks

Sam Snellgrove

-

12Phil Christopher July 5th, 2021

Hi Sam,

Thank you for your message. It’s always best to consider straw at the design stage, however you may be able to do something. It would probably be best to seek the advice of a straw bale specialist who can look at your current design in detail and give you some advice. Take a look at https://strawbalebuildinguk.com/members_directory#!directory/map

I wish you all the best with your project.

Phil

-

13Sam July 8th, 2021

Dear Phil.

Thankyou for your reply.

I have contacted Straw works in Devon.

Sam

-

14RichardC October 14th, 2021

Hi, I’m building a timber-framed garden room and looking for advice on whether I can get away with NOT rendering strawbales used for insulation (not load bearing). I did a LILI strawbale course circa 2003 and have a few books on the subject but none talk about alternatives to rendering or state categorically that render is always the only way to manage moisture (which is my concern).

I am hoping that it might be possible to avoid the hassle of lime rendering if i have a wall constructed as follows: timber structural frame with breather membrane, battens (to create ventilation space) then timber cladding on exterior side. On interior side would be: strawbale infill and a second, inner timber frame onto which is attached a vapour control layer (VCL) membrane (taping edges) and plywood sheets as wall finish. So, no moisture-impermeable layers that would trap humidity but no render. I’d use a rodent-proof metal mesh on the exterior side for that aspect of things.

The ‘cabin’ would not be for sleeping in and will likely have a woodburner. Maybe I could not render and monitor the moisture levels inside the bales with a probe.

Thanks for any insights, R

-

15Phil Christopher October 15th, 2021

Hi Richard,

The main risks to consider with straw walls are moisture, fire and fauna.

If the walls are suitably protected against rodents etc. then that leaves just the first two. If the straw is protected externally by rainscreen cladding you still need to consider general humidity levels. Depending on usage, the straw itself might well be okay, but interstitial condensation certainly needs to be considered. Whilst a well built straw wall should have zero gaps in the straw itself, any junctions and penetrations – top and bottom of the wall, doors, windows, services etc. – need to be detailed carefully to prevent moisture movement through the wall. Against the straw this could be very significant, regular moisture.

Tapes, plaster/render and membranes can all play a part in detailing this. An intelligent membrane that provides airtightness, but can also be vapour open might be a good choice. I really like clay plaster on straw as it helps regulate internal humidity and heat too.

That leaves fire. External bales behind cladding need some kind of fire proofing because the draught effect would draw fire up the gap very quickly. And whilst the bales themselves would take a very long time to burn, there would be fast surface spread. As you say, a coat of render is the traditional way to prevent this. It could be quite thin behind cladding, but thicker means longer protection. Clay could be used instead of lime, but clay will absorb moisture faster, so just be wary of that if external humidity is often high.

Panel systems often use boards across the straw surface such as wood fibre board etc, which give very good fire protection, but these are normally still finished with render of some sort.

Using common sense and observing any relevant regulations it is of course possible to experiment and carefully monitor how things are going, taking remedial action if necessary. I hope this helps!

-

16Amanda Cullen August 10th, 2022

Hi, I hope this thread is still live, I would love some advice please. I have wanted to build a straw bale house for a very long time, I learned how to do lime plastering when renovating an old cottage in Cumbria and love working with natural materials. I currently live in France but would like to move back to live in Dumfries and Galloway, and I am trying to find contacts there who might be able to help and advise me. Am I right in thinking that Steve James lives in that area, does he still help people out please?

Land costs a lot more in the UK than here in France, so I’m a little worried about my budget for the whole project. I would do as much of the work myself as I could, but getting to know some like-minded people who could also help out would be great, as I’ll need to spend time establishing an income. I can already do lime rendering, just need to learn the rest! Thank you for any advice and/or contacts you can give me, it would be so exciting to finally be able to do this. Amanda

-

17Rebecca Stacey August 11th, 2022

Hi there – we are still live!

I’ve passed on your commment to the specialist and will hopefully be able to provide you with an answer.

-

18Phil Christopher August 11th, 2022

Hi Amanda, Thank you for your question. Take a look at https://strawbalebuildinguk.com where there is a directory of folk who may be able to help. Or try contacting SBUK directly and they can put out a request to their members. Feel free to email me ([email protected]) if I can be of further assistance. I hope you can build your home! All the best, Phil.

-

19Amanda Cullen August 23rd, 2022

Hi Rebecca and Phil,

Thank you for your replies, sorry, I’ve been a bit slow finding them. I will have a look at the website to find out more. If I’m going to build the house I have always wanted it’s now or never really, I need to get an idea of approximate cost of build to see if it is viable for me to return to the UK to do it. I would love to do some of the work myself to keep costs down, but would also need to be working on establishing an income, so a balance needs to be struck. I will contact SBUK to see if there is anyone who can give me a rough idea.

A random question to throw at you – is it possible to use straw bales to line the inside walls of an old stone cottage, then render on top? The one I have in mind would be just 4 walls and a roof, no internal walls as yet.

Thanks very much, Amanda

-

20Ruth O'Brien January 25th, 2023

Hello,

I would like to do your online strawbale course, but unfortunately I can’t seem to get registration and login to work to enrol. Could anyone help me to get registered? I would be very grateful.

Many thanks,

Ruth

-

21Dave Darby January 25th, 2023

Hi Ruth – I’ve emailed you.

-

22[email protected] February 13th, 2023

How long is the course? And when? I may have missed the last. Many thanks. Best wishes.

-

23Dave Darby February 13th, 2023

Jonathan – they’re ongoing. Take it at your own pace. No start and finish dates/times.

-

24Victor September 6th, 2023

Hi everyone.

I just purchased the course and looking forward to learn about its contents.

I have a question though. I am looking for ways to combine straw bale construction with wooden structure but with an exterior finishing out of stone masonry. The idea is to make the house look like the vernacular architecture of the place, which is basically made of stone masonry, brick and mortar mountain houses. By any chance do you know whether it is possible to combine in the walls these two different layers of materials? Wooden frame structure and straw bales in the interior side of the walls and stone and old bricks masonry on the outside.

Any recommendation?

Thank you so much for your assistance.

-

25Rebecca Stacey September 6th, 2023

Hi Victor - I'll bring your attention to our experts - and do let us know how you get on with the course.

-

26Marcela Moreno April 23rd, 2024

Hi. My name is Marcela Moreno ; some time ago I payed for the course to build with straw bales.

today I want to start my course, how can I do? the id I have is no working.

could you help me please?

-

27Rebecca Stacey April 24th, 2024

HI Marcela, if you could contact us directly please: [email protected] - I can help you!

Low-impact building

Low-impact building

Clay & earth plasters

Clay & earth plasters

Lime

Lime

Planning permission

Planning permission